March 2019 – Feature

Dry Deluge Testing – reducing corrosion and blocked nozzles

Pivotal to the protection of personnel and the asset is a well maintained and blockage free deluge system. Having a deluge system with clean nozzles and piping is essential to providing the flow of water to a protected area. Testing regimes using water cause corrosion and the build up of marine life within even the newest deluge systems. Water testing also causes increased corrosion on the structure and requires areas to be shut down until the testing is completed.

The Siron Dry Deluge Testing technology is a patented vapor based test that will eliminate many of the issues caused by wet testing. The testing is done with very minimal impact to personnel working within the tested areas. Production activities can continue and the deluge system remains live whilst the testing is being carried out. Testing is done in sections, each taking approximately one day. Open, blocked and partially blocked nozzles are marked on isometric drawings during the test.

As no water is being used the facility personnel do not need to cover production or electrical equipment with the additional bonus of no after test fresh water wash down and clean up. This technology is suitable for old and new facilities regardless of deluge specifications as all systems suffer from marine life growth, corrosion or both!

Older systems can be cleaned, descaled and have corrosion inhibitor applied to give the system the best chance of performing as required.

This technology has been tested and is in use already by Oil & Gas operators in Europe and the United States of America.

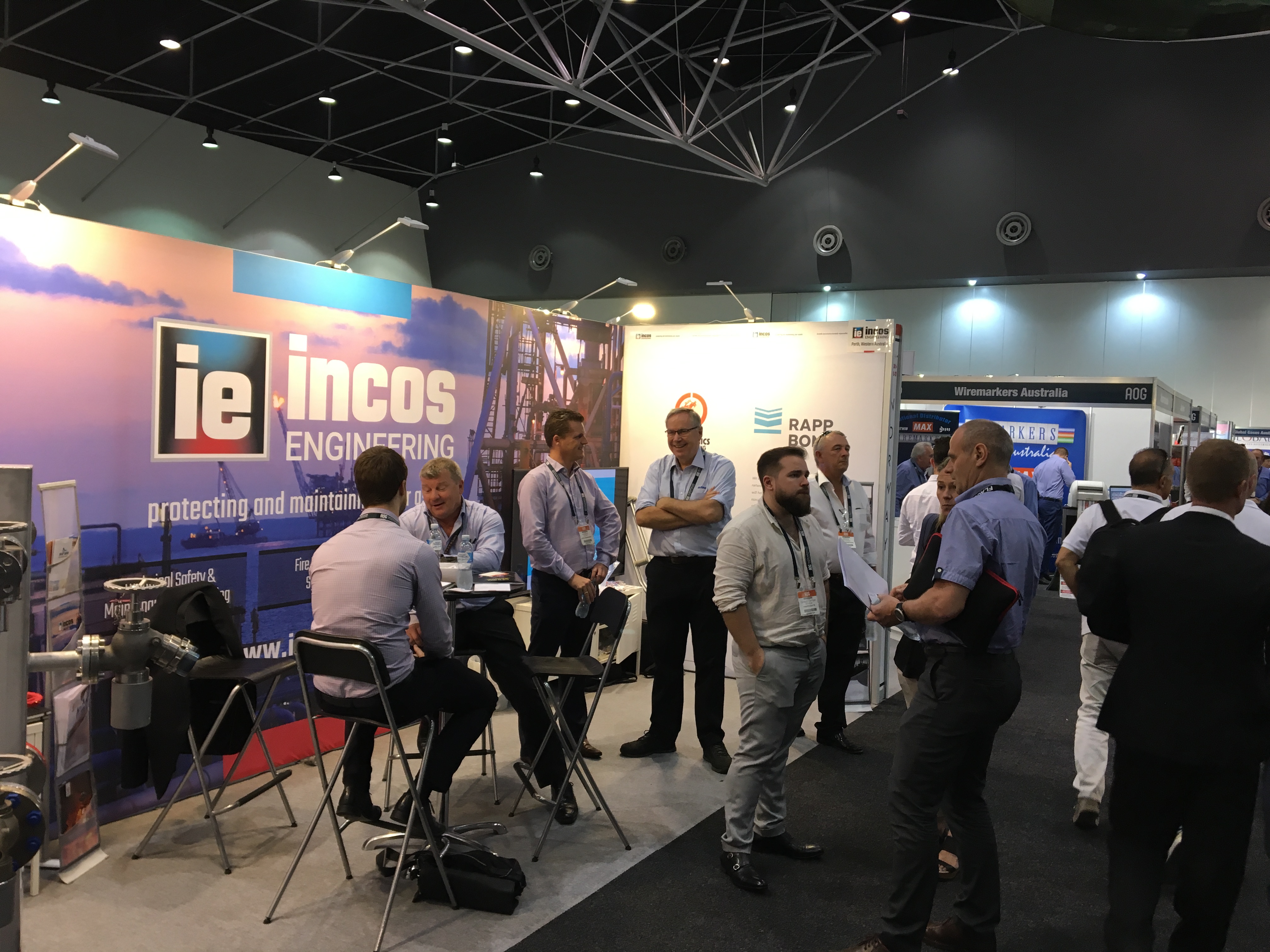

Australasian Oil & Gas Exhibition (AOG) 2019

From 13th – 15th March Incos Engineering exhibited at AOG in Perth, Western Australia. This was our first exhibition and conference as I.E and we thank all those who visited our stand. We had many discussions about fire protection and our ability as a local provider to support Australian Industry Participation guidelines and Local Content requirements.

Did you know you can refurbish Inbal Valves?

Inbal offer an excellent range of deluge valves suited to the Oil & Gas industry and are widely used. They offer a very good service life and are able to be refurbished at around half the cost of buying a new valve. Inbal valves can be assessed and refurbished at our workshop in Perth.